1.preface

In line with the development trend of green and low-carbon transformation in the steel industry, the frequency conversion transformation equipment upgrade of Ningbo Steel plant has been completed recently. The project seamlessly replaces the original electrical equipment of the pipe coal conveyor, and realizes the upgrade of the communication system from C network to Ethernet/IP. Three sets of FD800 engineering transmission and control system online switching host design, to ensure the continuity of equipment operation, greatly improve the efficiency of iron and steel enterprises. It marks the development of new quality productivity of FGI and the promotion of high-end equipment localization process to a new level.

2.FGI upgrade solution

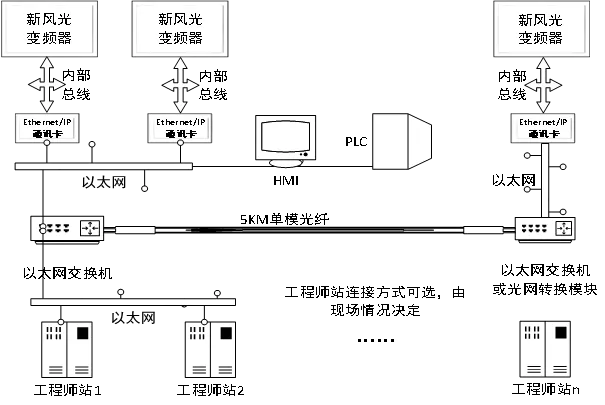

The distance between the two plant areas of the steel mill and the coking plant is 3.6 kilometers. The raw coal is processed in the coking plant and transported to the steel mill. In order to reduce pollution, the clean coal is transferred between the two plants by a pipe belt machine.

(1).frequency inverter transformation

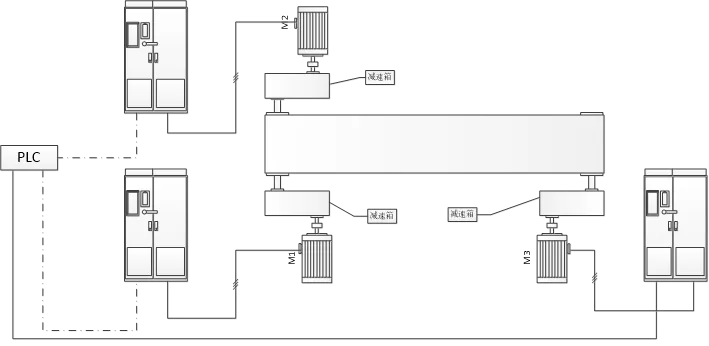

The pipe belt machine adopts the mechanical transmission scheme of "first two and last one", and implements the communication upgrade and frequency conversion upgrade step by step according to the factory operation maintenance time. After the transformation is completed, the system has a master and two slave working mode. When one of the equipment is faulty, the master and slave machine can be switched by PLC to realize the control of one master and one slave, and ensure the equipment can operate normally without stopping.

(2).Control system transformation

According to the existing control scheme of the coking plant, FGI upgraded the original PLC controller, and transformed the control network from ControlNet to EtherNet/IP Ethernet communication, and replaced the original multi-mode optical fiber communication between the main plant transfer station and C304 transfer station with single-mode optical fiber communication to improve the reliability of information transmission.

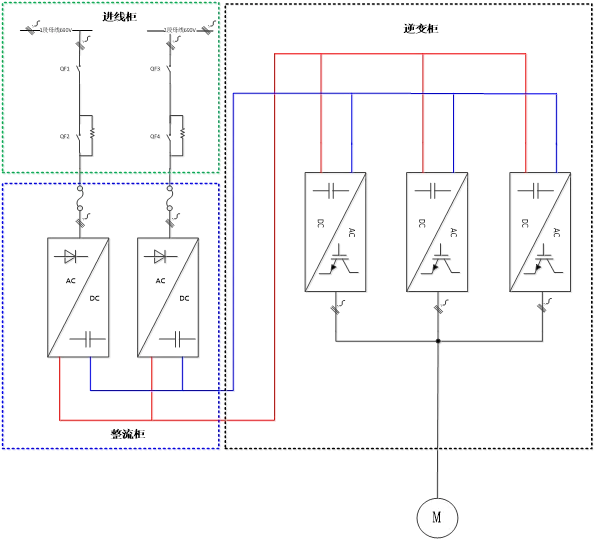

In response to the transformation needs, the driving equipment is selected FGI's new generation FD800 engineering transmission series products, the model is FD800-60F-1500-6, and the engineering transmission frequency converter is composed of three parts: incoming cabinet, rectifier cabinet and inverter cabinet. The product has the advantages of control precision, environmental protection and higher efficiency.

3.product feature

(1)FD800 frequency inverter optical fiber communication technology, to achieve distributed installation of control unit and power unit, EMC performance is more superior.

(2)FD800 frequency inverter drive synchronous wave technology, unit uneven mobility control within 1%, breaking new heights in the industry.

(3)FD800 frequency inverter power terminal high current plug technology, more convenient maintenance, power unit replacement can be controlled within 10min.

(4)FD800 frequency inverter power unit redundancy control technology, can achieve power unit fault bypass, derating use, safe operation without shutdown.

4.Four customer values

(1)Long distance transmission: achieve 4km long distance transmission of a single coal conveyor, breaking the new length of the industry.

(2)Continuous work: excellent master-slave control technology, to achieve motor power balance, and can achieve one master two slave, one master one slave free switching, greatly improve the continuity of equipment operation.

(3)High-end replacement: complete the seamless replacement of imported brands, and solve the "stuck neck" problem of core technology in key process links.

(4)Network upgrade: from ControlNet to Ethernet, communication speed and stability are greatly improved.