1.Introduction

With the growth of population and the development of the economy, the first major livelihood project of Dushan County during the 12th Five-Year Plan period, Dushan Waterworks, has newly built a 50,000-ton-per-day water supply project in the near future on the basis of the original one, and plans to expand the water supply to 100,000 tons per day in the long term. Provide sufficient tap water for the citizens of Dushan County. As Dushan County is located on the Yunnan-Guizhou Plateau, the entire area is situated on a box-shaped anticline that transitions from the Guizhou Plateau to the Guangxi Hills, forming a protruding platform that is 310 to 490 meters higher than the surrounding areas. The lowest altitude is 500 meters, the highest is 1,465 meters, and the average altitude is between 850 and 1,100 meters. The water supply pump room is equipped with 6 315kw/10kv water pumps. Due to the significant difference in water supply between day and night. The frequent start and stop of such water pumps will cause an increase in the failure rate of motors, water pumps and valves, raise maintenance costs, and at the same time have a significant impact on the power grid and pipeline network.

2.Introduction to the Production process of Tap water in Dushan County

The daily water supply capacity of the waterworks is determined based on the water supply range and the number of residents using it. The production processes of waterworks of different sizes are basically the same, including water source, water intake, mixing, reaction, sedimentation, filtration, disinfection and water supply.

First, select an appropriate water source and send the water to the factory's water treatment system through the primary pump room (water intake pump). After mechanical mixing and coagulation reaction treatment, the colloidal particles and tiny suspended solids that are difficult to settle in the water can be destabilized and accumulated with each other, eventually forming larger flocs, which are convenient for separation and sedimentation from the water. The purpose of mechanical mixing is to rapidly and evenly dissolve the chemicals in water through vigorous stirring by hydraulic and mechanical means, thereby enhancing the coagulation efficiency. After passing through the coagulation reaction, it enters the sedimentation tank. The flocculent substances formed are separated from the water by the force of gravity, and the particles settle to the bottom of the tank. The sludge that settles at the bottom of the pool continuously accumulates and concentrates, and is regularly discharged outside the pool. Filtration is to further remove fine suspended impurities from water. After filtration, the water is treated by a chlorination disinfection system to destroy the bacterial enzyme system and kill the bacteria. The disinfected water is lifted to a certain water pressure from the clear water tank through the water supply pump room, and then delivered to thousands of households through the water transmission and distribution network.

3.The principle of FGI FD5000 series medium voltage drive

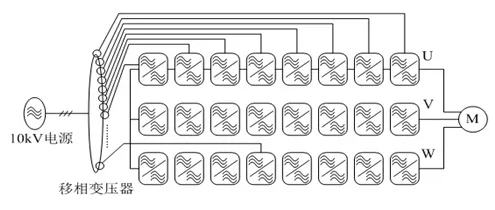

The topological structure adopted by the FGI FD5000 series series medium voltage drive is the unit series type high-voltage frequency converter, which is a direct high-high conversion voltage source type.

The medium voltage drive takes power from the 10kV power grid, and after passing through the internal phase-shifting transformer for voltage reduction, phase shifting and isolation, it is delivered to each power unit. In principle, each power unit is equivalent to a low-voltage frequency converter with three-phase AC input and single-phase AC output.

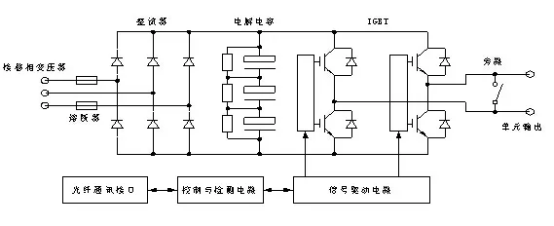

The rectifier circuit of the power unit is diode full-wave rectification. The rectification mode composed of multiple pulses and multi-pole shift phase superposition greatly improves the current waveform on the grid side, making the power factor on the grid side under load greater than 0.95. The output side supplies power to the motor in a star connection formed by the U and V output terminals of each power unit being connected in series. By performing sinusoidal SVPWM control on the IGBT inverter bridge, a stepped SVPWM waveform is obtained. This waveform has a good sinusoidal degree and a small dv/dt, which can reduce the output harmonics and the motor heating and noise caused thereby. This reduces the insulation damage to the output cable and the motor, eliminates the need for an output filter, and can directly drive a common asynchronous motor. Meanwhile, the mechanical vibration caused thereby is eliminated, and the mechanical stress of the bearings and blades is reduced. Through software control, different levels of frequency voltages can be output. The FGI FD5000 series medium voltage drive system is safe and reliable. The protection devices are fully functional, featuring protection devices such as overvoltage, undervoltage, overcurrent, overheating and phase loss. It has a complete fault monitoring circuit and precise fault alarm protection.

4.The features of the FGI FD5000 medium voltage drive

(1) Integrated design makes the system more concise, easier to maintain and has higher security performance.

(2) Input current-limiting function: By adding a current-limiting resistor, the inrush current to the upper-level switch when the high-voltage frequency converter is powered on can be reduced, achieving soft charging.

(3) The modular design of the unit and the dual-redundant mechanical unit bypass technology offer stronger anti-interference ability and higher reliability. The structure and electrical performance of each power unit are consistent and they can be used interchangeably.

(4) It is equipped with unit bypass technology. When a certain unit malfunctions, the faulty unit can be bypassed to achieve bypass operation without stopping the machine, ensuring the continuity of production.

(5) AVR automatic voltage stabilization function: When the input grid voltage fluctuates, the AVR function can keep the output voltage of the frequency converter unaffected.

(6) Dual power supply redundancy design, powered by two separate power supplies, is more reliable than traditional UPS solutions.

(7) "Flying Car" start function: When the motor is still rotating, it can be directly started through speed tracking technology without inrush current.

(8) SVPWM space voltage vector control ensures high utilization of DC bus voltage, which can increase the output voltage by 15%.