Summary: In this paper, through introducing FGI FD5000 series high voltage frequency inverter applied to pulper in the papermaking factory in Russia, to illustrate VFD transformation of the feasibility and many advantages after using FD drives.

1. Project overview

The pulper is an important device at the beginning of the process of papermaking. The pulper is mixed the recyclable paper and water equably, after mixing and stirring they become pulp.

In traditional ways, the papermaking factory use grid power directly driving the pulper. There are lots of disadvantages by this way. Such as large impact current when starting the pulper, can’t automatic controlled by DCS or PC system, easily blocked by plastic and etc. These problems always perplex the papermaking factory.

As the development of frequency inverter technology, many papermaking factory customers realize that using frequency inverter to drive pulper is much better than original ways.

2. Application solution

EEFFK papermaking factory is very big factory in Russia. The average production of paper capacity is about 1000 tons/day.

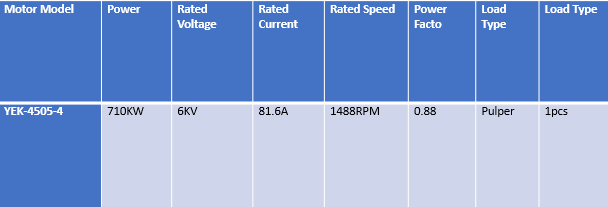

Detailed motor parameters are list as follow:

Table 1 Motor Parameters

On-site pictures:

Figure 1, the recyclable paper conveyor

Figure 2, the paper production

3. System Configuration

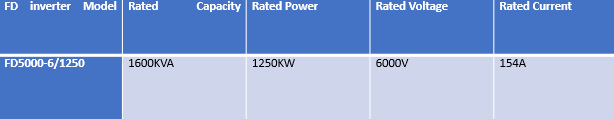

According to the customer requirement, we choose the FD5000 series high voltage frequency inverter, produced by FThe FD5000 series high voltage frequency inverter model is FD5000-6/1250 with bypass cabinet. Below table is the details of FD inverter parameters:

Table 2 FD inverter Parameters

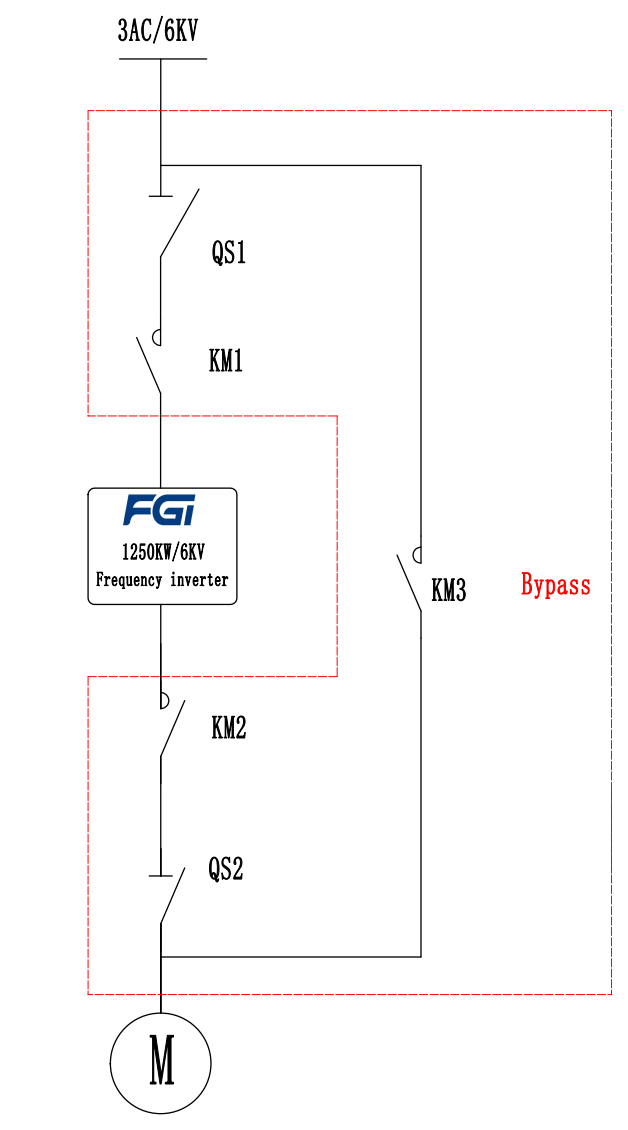

Below figure is about inverter system diagram:

Figure 3, System diagram of the inverter

On-site pictures:

Figure 4, FD5000 frequency inverter

4. Application and Advantage

After using FGIFD5000 high voltage frequency inverter, there are some advantages as follow,

1) Soft start; The speed of pulper can running from 0 to rated speed, the acceleration time adjustable as the customer need.

2) Easily control by DCS; With digital and analog connection, it is easy to control;

3) Low harmonic. Without harmonic pollution to the motor and efficiently drop the heat of the motor. Increase the input power factor.

4) Reduce the loss of shutdown maintenance and save plenty of maintenance costs.

5) Running direction flexibility. When the customer find the pulper is blocked, they can use reversal jog function, after running at reversal state for some seconds the pulper continue running at forward state.

5. Conclusion

After using FGI FD5000 series high voltage frequency inverter to drive pulper, the inverter can meet with the customer requirement, which can automatic control by DCS system and soft start. Good operation of the inverter, obtained the customer widely recognized.