1.Overview

With the continuous improvement of process requirements, industrial washing machine develops from ordinary type to automatic type, at present, most of the automatic industrial washing machine uses multiple double-speed AC motors, because of the simple structure, firm, cheap price and other characteristics, has been widely used. But its disadvantage is the poor speed performance, speed mutation, vibration. With the development of power semiconductor technology, in recent years, the ac frequency conversion governor has been relatively popular in industrial washing machine, industrial washing machine inverter requirement is higher and higher, requirements can meet the requirements of industrial washing machine is high start torque, multiple speed, wide voltage range, automatic differential compensation and fast and powerful communication and other technical difficulties. And the performance is stable, can adapt to a variety of complex high temperature, high humidity environment.

2.Implementation plans:

Fully automatic industrial washing machine refers to the large capacity washing machine with initial washing, rinsing, bleaching and dehydration functions, and between the functions do not need manual operation, can realize automatic conversion. The working principle of automatic industrial washing machine is that under the unified scheduling management of the timing controller, the asynchronous motor is controlled by the frequency inverter to continuously execute the positive and back rotation to realize the unsynchronous movement of water and clothes, so that the water and clothes rub each other to achieve the purpose of washing. Transmission system is an extremely important part of industrial washing machine, because it mainly provides power support for washing machine and participates in the whole washing process. The transmission system is composed of electric motor and various variable speed mechanisms. Now, it mainly uses frequency inverter, so it significantly simplifies its components, which is generally composed of frequency inverter, asynchronous motor, pulley and transmission belt. In the whole washing stage, with the frequency automatic adjustment of the frequency inverter, the constant torque change of no impact, no intermediate transition (transmission, transmission device, coupling, clutch, etc.) (cascade speed regulation), so that the energy consumption of the washing process is significantly reduced.

Automatic industrial washing machine requires the frequency inverter to provide high torque, multi-segment speed, wide voltage range and automatic turn difference compensation. The main role of the frequency inverter in the system is to adjust the speed of the washing machine, so that the washing machine is in a low speed state in the washing cycle, and has a very smooth torque. During the dehydration cycle, with a high speed of rotation. It also can set the frequency flexibly, which is conducive to speed regulation, so that it can make the system steady state operation, and can reduce mechanical wear, prolong the service life of industrial washing machine. FGI FD100 Series frequency inverter, the frequency inverter has a large starting torque, smooth operation, perfect fault protection measures and other excellent performance. The frequency inverter adopts the wide voltage design 330V-440V, the starting torque can reach 150% under 0.3 HZ, the automatic torque lifting function controls the low frequency large output torque in SVC, the 16 section speed can meet the multi-stage speed control mode in various occasions, the speed regulation range is wide, the acceleration and deceleration process does not stall, and the whole speed is stable.

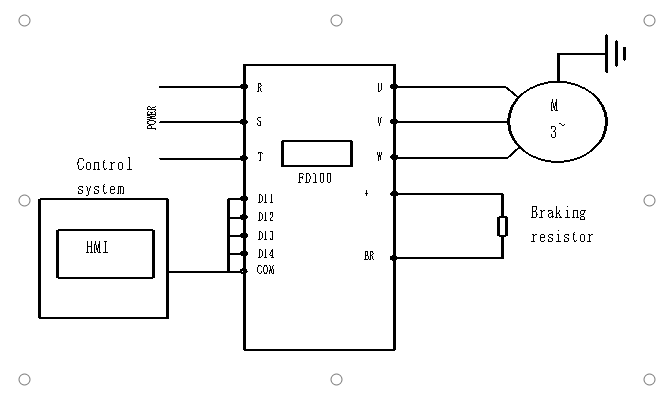

Power converter wiring diagram:

3.Note

The frequency inverter is applied in industrial washing machines. If the torque is found to be not enough, the frequency inverter is not able to accurately learn the motor parameters when using vector control. If the self-learning is not successful or accurate, it is recommended to use VF mode.

Fully automatic industrial washing machine because of its process procedure requirements, in the selection of frequency inverter, is generally equipped with the washing machine on the basis of the motor rated power, amplification of a power level equipped with frequency inverter. The specific standard is that the laundry weight is the rated power of the frequency inverter * 10 (Kg), and the laundry weight is the rated power of the frequency inverter * 10 (Kg) the converter needs to customize the VF curve. If the frequency inverter increases the first gear, basically do not customize the VF curve, only need to set the functional parameters

Considering the field usage conditions, please note the following points:

(1). Due to more signal lines of the whole system, more electronic and electrical equipment, the frequency inverter control line and power line should be connected separately to prevent interference;

(2). When installation, attention should be paid to the installation position to ensure the smooth heat dissipation channel and meet the heat dissipation requirements;

(3).waterproof, anti-corrosion to do well.