1.Overview

The copper refinery under the Mining and Metallurgical Group is a large state-owned enterprise in China. With the increasingly strict requirements for the treatment of copper smelting furnace exhaust gas in China, the leaders of the company, after considering various factors, feel that the treatment of exhaust gas is cleaner and more effective. The exhaust gas is purified and the SO2 is converted into sulfuric acid. And also produced a new product - sulfuric acid; It can not only increase new economic benefits, but also achieve the purpose of killing two birds with one stone.

2. Implementation plans

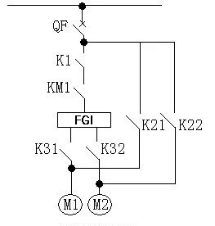

According to the needs of customers, two sets of fans and a set of frequency conversion speed regulation device are installed on the site, that is, one frequency inverter drives two motors. The company can according to the use of the environment and customer needs, equipped with FD5000 type high power, high voltage frequency inverter speed regulation device.

3.Application advantage

(1) The smooth start of the system is realized. The equipment is equipped with a new machine. Due to the small configuration of the system power grid, the power frequency is directly started, and the current is about 5-7 times of the rated current, that is, the start moment can reach about 300A, which can not be started when the air door is opened. With frequency conversion to start, the starting current is about half of the rated current (about 28A) can be stable and normal start, so the soft start problem is solved.

(2) Smooth and uninterrupted speed adjustment during operation. The frequency of the inverter can be smoothly adjusted according to the process requirements, and then the speed of the motor can be adjusted continuously, so that the transmission of SO2 can achieve stepless smooth adjustment, reduce the impact on the damper and the system, and greatly prevent the impact of the pipeline system.

(3) The system has the advantages of simple operation, convenient operation and low labor intensity. Especially, it adopts automatic control technology to realize unattended inverter.

(4) Significant energy saving.For fan/pump loads, fluid mechanics knows that the flow is proportional to the speed, the pipe pressure is proportional to the square of the speed, and the shaft power is proportional to the cube of the speed.

Now the system operates at 40Hz, so the power supply runs under frequency inverter. P change = (40/50)3P worker =0.83 3P worker =0.51 P worker

Of course, the efficiency of the inverter may be reduced, and the overall efficiency is about 80%. Therefore, the actual efficiency after the application of the inverter is P1 variable = 0.51/80% P = 0.64P =64% P.

Then the power saving rate is P= (P worker - p1 variable)/ P worker =36%

The power saving effect is very obvious, and the expected energy saving effect has been basically achieved.

In short, after using the inverter, the device has the advantages of soft start, stable work, energy saving, etc. It is an ideal automatic control device, and has a wide application prospect.