Recently, North China Oilfield Renqiu City west Hailan City oil field waste heat heating project put into use, the project is the key project of the oil field company in 2024, after the completion of the project, built a central heat source station, 12 geothermal Wells, 13 block heat exchange stations, heating network 12 kilometers, heating users of nearly 20,000 households, the formation of a total scale of 3 million square meters of heating capacity. In the project, the mature submersible electric pump oil extraction technology is applied to the extraction of underground hot water source to solve the difficulty of pumping water at a depth of 400 meters underground, among which the FGI 3 sets of special inverter for submersible electric pump are adopted to realize the long-distance drive of the submersible pump, energy saving and consumption reduction.

1.Application Analysis

Submersible electric pump is a multi-stage centrifugal pump that works in the well. It is an oil production equipment that uses tubing to put the centrifugal pump and submersible motor into the well, and the motor drives the multi-stage centrifugal pump to rotate and generate centrifugal force to lift the crude oil in the well to the surface. It is a rodless pump oil production equipment that is widely used in various oil fields.

The electric submersible pump driven by frequency conversion is more and more widely used. By driving the oil pump unit by frequency conversion, soft start can be realized, which eliminates the impact of underground machinery and electricity, makes the pump work in the best working condition, and is conducive to extending the service life of the oil pump unit.

There are two main problems in the application of electric submersible pump, one is how to save energy, and the other is how to control the electric submersible pump to make it work in the best condition. Electric submersible pump is working at the bottom of the well below 2km on the ground, the working environment is very harsh (high temperature, strong temperature, etc.), generally using the traditional power supply mode, that is, working at power frequency full pressure, so frequent failures and high operating costs.

2.FGI electric submersible pump frequency conversion special machine

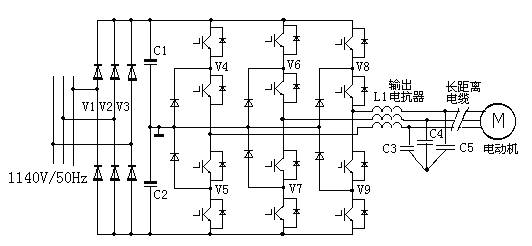

FGIFD3000 series control cabinet provides AC power for submersible electric pump unit, equipped with PCC or DPCC protection control instrument, which can provide short circuit, over current, under load, over load and lack of equal protection for downhole submersible electric pump device, and realize manual or automatic operation of starting or stopping the submersible electric pump.

Submersible electric pump split frequency conversion control cabinet The frequency conversion cabinet has short circuit, overload, underload pressure and temperature protection, as well as voltage, current and the corresponding protection signal lamp indication, and can be manually and automatically controlled by the internal setting of the inverter and the configuration of external components, greatly saving labor costs.