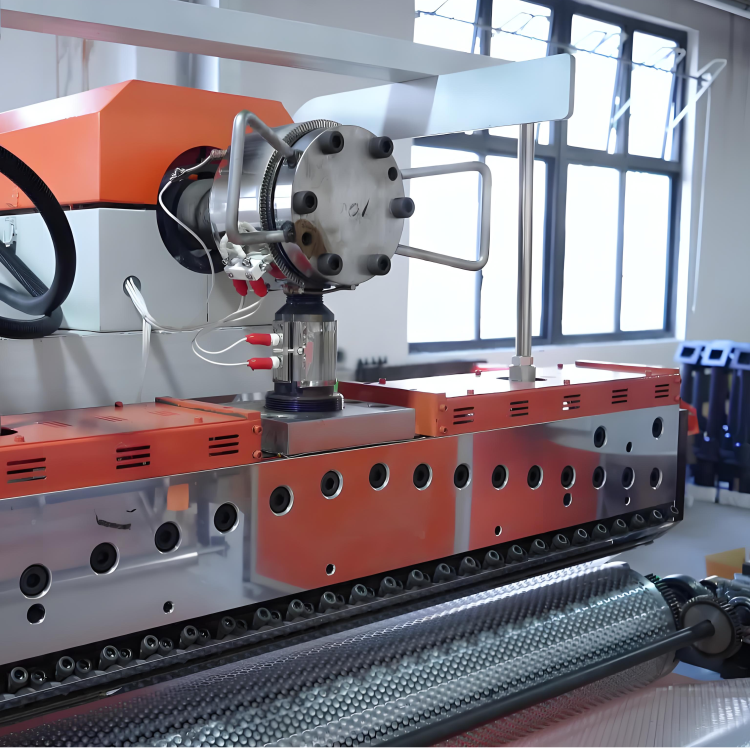

Bubble film machinery is an essential tool in the packaging industry, used to create protective cushioning for fragile items during transport. The efficiency and effectiveness of this machinery depend on various components, including frequency converters. In this article, we will explore the application of the FD500 frequency converter in bubble film machinery and how it enhances the performance of the equipment.

1. Introduction to FD500 Frequency Converter

The FD500 frequency converter, manufactured by FGI, is a state-of-the-art product designed to control the speed and torque of electric motors in industrial applications. With its advanced technology and user-friendly interface, the FD500 has become a popular choice for machinery manufacturers looking to optimize the performance of their equipment.

2. Benefits of Using FD500 Frequency Converter in Bubble Film Machinery

One of the key benefits of using the FD500 frequency converter in bubble film machinery is its precise speed control capabilities. This allows operators to adjust the speed of the motor according to the requirements of the production process, leading to a more consistent and high-quality output.

In addition, the FD500 frequency converter is equipped with various protective features, such as overcurrent and overvoltage protection, which help to prevent damage to the motor and other components of the machinery. This increases the reliability and longevity of the equipment, reducing maintenance costs and downtime.

3. Enhanced Energy Efficiency

Another advantage of using the FD500 frequency converter in bubble film machinery is its energy-saving capabilities. By adjusting the speed of the motor to match the actual load requirements, the FD500 can reduce energy consumption and lower operating costs. This not only benefits the environment but also improves the overall profitability of the production process.

4. Easy Installation and Integration

The FD500 frequency converter is designed for easy installation and integration into existing bubble film machinery. Its compact size and user-friendly interface make it simple for operators to set up and configure the device according to their specific requirements. In addition, the FD500 is compatible with a wide range of motor types, making it a versatile solution for different applications.

5. Remote Monitoring and Control

One of the key features of the FD500 frequency converter is its remote monitoring and control capabilities. Operators can access the device's settings and performance data remotely, allowing them to make real-time adjustments and troubleshoot any issues without having to be physically present at the equipment. This enhances the efficiency of maintenance and troubleshooting processes, reducing downtime and improving overall productivity.

6. Conclusion

In conclusion, the application of the FD500 frequency converter in bubble film machinery offers numerous advantages, including precise speed control, energy efficiency, and easy installation. With its advanced technology and user-friendly interface, the FD500 enhances the performance and reliability of the equipment, ultimately leading to a more efficient and cost-effective production process. By choosing FGI's FD500 frequency converter, manufacturers can optimize the performance of their bubble film machinery and stay ahead of the competition in the packaging industry.