1.Overview

Air compressor is the equipment that provides air source power, is the core of the pneumatic system, is the basic product of industrial modernization, and converts the original dynamic mechanical energy into gas pressure energy device. Widely used in production lines, machine tools and all the use of compressed air occasions.

2.Implementation plans

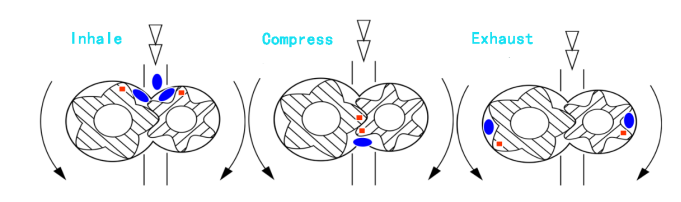

(1).Inspiratory phase

The rotor rotates, and the intake end gap begins to fill through the suction port, while another pair of convex angles is ready to compress, which ends when filling over its entire length.

(2).Compression stage

The Yang rotor convex angle begins to engage with the corresponding Yin rotor, and when the two convex angles pass through the sealing line, the air will intercept the Yang convex angle and begin to squeeze the intercepted air.

(3).The exhaust stage

The extrusion movement of the Yang rotor gradually reduces the volume of the trapped air and simultaneously squeezes it to the exhaust end to complete the exhaust air.

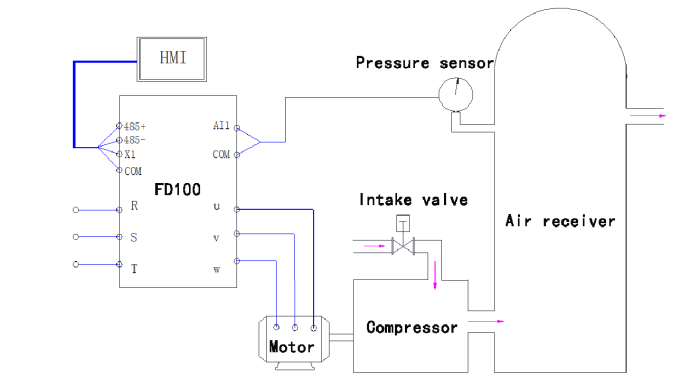

The system adopts the PID function of FGI FD100 low voltage frequency inverter for constant voltage control.

The system composition is as shown in the figure below:

3. Application advantages

(1).FGI FD100 low voltage frequency inverter vector control, fast response speed, stable running speed;

(2).FGI FD100 low voltage frequency inverter parameters and system control parameters can be set by touch screen;

(3).FGI FD100 low voltage frequency inverter has excellent pressure PID control function to ensure stable air supply pressure of air compressor equipment;

(4).FGI FD100 low voltage frequency inverter has good soft start function, prevent impact, reduce noise;

(5).FGI FD100 low voltage frequency inverter has intelligent sleep and multiple operation protection functions.