1.introduction

Since its inception, FGI has adhered to the path of professional development. The production of biological fermentation special frequency inverter has been widely used in the pharmaceutical industry 15 years ago, of which the typical supporting manufacturers are Henan Xinxiang Huaxing Pharmaceutical factory, Shandong Qifa Pharmaceutical, etc., which replaced the imported brand frequency inverter earlier.

The fermenter controls the motor speed through the frequency converter to further control the stirring speed of the stirring device in the fermenter, to meet the needs of some materials according to different fermentation stages, to achieve fermentation process regulation, to meet the process and quality requirements, and to promote the fermentation process research; At the same time to achieve energy saving and consumption reduction, reduce electrical, mechanical impact, reduce mechanical loss and maintenance workload, extend the service life of equipment, very good benefits.

2.Scheme design and description

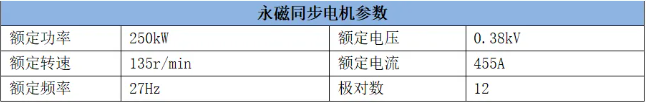

The 380V/250KW permanent magnet synchronous motor driven stirring equipment of domestic large pharmaceutical companies is explained. The permanent magnet motor direct drive stirring system is used to cancel the reducer device, which has simple structure, small volume, lower loss, simple maintenance and installation.

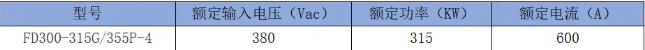

According to the requirements of the system scheme for the frequency inverter, the FGI FD300 series of high-performance vector frequency inverter is selected. In order to cope with the complex power grid environment on site, input and output reactors are installed. Through the high-performance permanent magnet synchronous motor control algorithm, the shaft reversal problem is solved during the startup process, and stepless speed regulation is realized to improve the production process.

FD300 frequency inverter product design features and advantages

● Book design, easy integration

● Synchronous asynchronous integration, drive control freely

● Variety of motor tuning, accurate parameters

● Multiple protection technology, safe and reliable

● Mainstream industrial communication, widely used

● Multi-channel expansion card slot, rich configuration

● A variety of braking methods, quick stop

● Speed tracking technology, smooth start

3.application performance

In this pharmaceutical mixing project, FD300 high-performance vector frequency inverter provided by FGI can fully meet the system load control requirements of variable frequency speed regulation, ensure the reliable and efficient operation of biopharmaceutical equipment, marking FGI's implementation of the national "carbon peak carbon neutral" strategy, and promote the substitution process of China's intelligent manufacturing. It has achieved new breakthroughs in product technology innovation and market expansion.

(1) The frequency conversion speed regulation method increases the controllability of process and quality, which has good research value for the pharmacology and quality regulation of drug manufacturing.

(2) The soft start function of the frequency inverter will make the starting current start from zero, and the maximum value will not exceed the rated current, reducing the impact on the power grid and the demand for power supply capacity.

(3) Reduce the mechanical shock and vibration, greatly reduce the mechanical damage and wear caused by mechanical shock and vibration, but also reduce the maintenance workload and maintenance costs of equipment, extend the service life of equipment.

(4) Make the agitation fermentation process flexible grasp, promote the research of pharmaceutical technology.