1. Overview

The plastic buckle plate extruder consists of extrusion, heating, forming, traction and cutting. After the plastic raw material is heated and dissolved, it extrudes to the molding mechanism through the extruder into the required shape, sends away the molded plastic buckle plate through the traction motor, and finally cuts according to the required length.The control principle of the traction motor is mainly expounded here.

When the speed of the extruder is certain, the need for traction motor and extrusion speed to maintain in a certain range of error, traction is too slow, the plastic buckle plate will become wide, otherwise it will become narrow.

In order to ensure the consistent width of the buckle plate, the traction speed; infrared switch is installed on the edges of the buckle plate, the width of the buckle plate needs to increase the traction speed; When the buckle plate edge does not block the infrared line, the buckle plate is not wide enough to reduce the traction speed.By continuously improving and reducing the traction speed, the traction motor is kept working at a critical value, so as to ensure the consistent width of the buckle plate.

2. Implementation plans

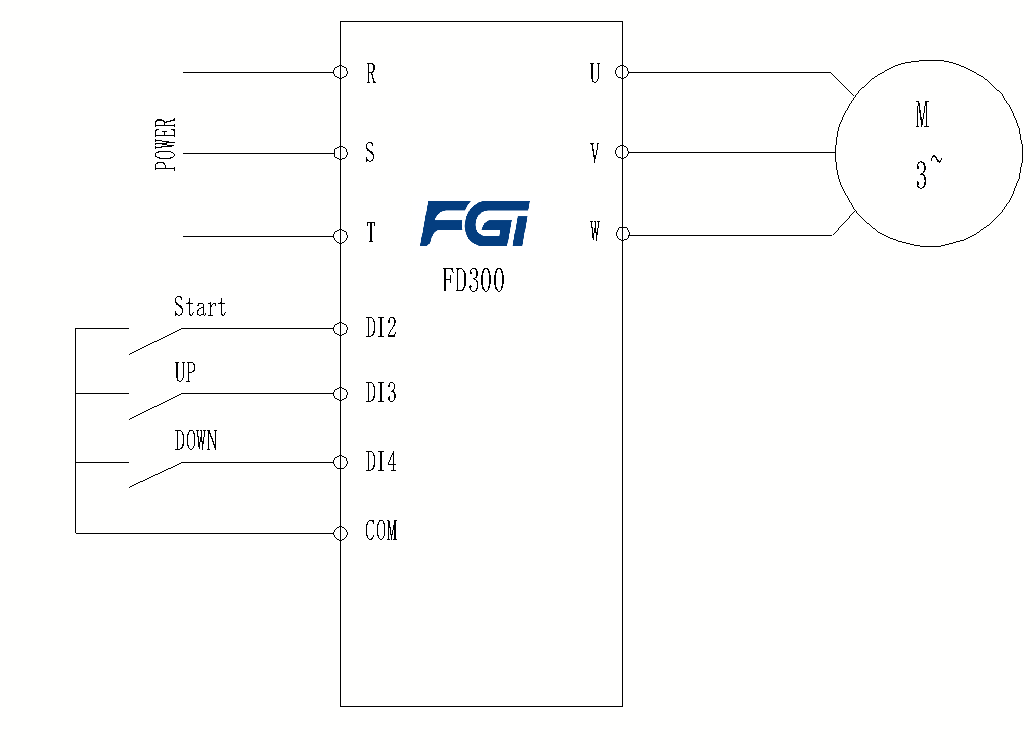

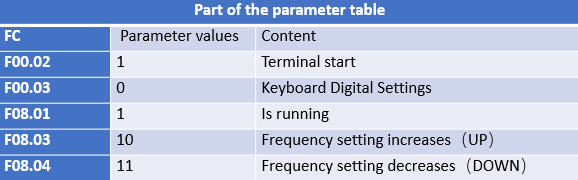

We will use FD300 frequency inverter to solve these problems.According to the working principle of traction motor, the traction motor is used to control the speed, the infrared switch passes the traction deceleration, and the acceleration; according to the working condition, the frequency source is the frequency source, the keyboard UP / DOWN can be modified; power loss is not; the frequency source is selected as one bit: main and auxiliary operation results, ten: main + auxiliary; infrared switch is often closed to DI3 and COM, often open connection DI4 and COM; the schematic diagram is as follows:

3. Application advantage

(1) The application of FD300 frequency inverter technology makes the running speed stable.

(2) Improve product quality.