1. Overview

At the present stage, the ecological and environmental pollution caused by municipal solid waste has become a social problem, which has increasingly attracted people's attention and attention. Waste incineration and power generation is becoming an effective means for the industry to solve this problem. In the traditional mode, there is an obvious resource consumption phenomenon in the water pump operation. In order to ensure the full play of the effect of energy saving and consumption reduction, the actual operation of the pump. The environmental protection feedwater pump project of Tianying uses FD5000 high voltage frequency inverter produced by FGI company to implement frequency conversion and energy saving control, which can effectively alleviate the pressure of the feedwater pump unit pipe network, and also minimize the solar term loss of the pump, so that the economic benefits of the unit can be comprehensively improved.

2. Implementation plans

The project adopts FGI FD5000 high voltage frequency inverter, supporting high performance, high energy saving frequency conversion control system and combined with advanced pump control technology to provide control scheme for the pump motor.

2.1 Main circuit design

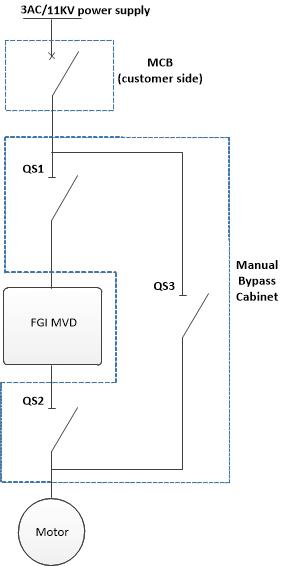

This design scheme is variable frequency power frequency all-in-one mode. When frequency conversion fails, power frequency mode can be used to continue the equipment and effectively avoid production loss. Through the frequency of adjustment setting to further meet the requirements of water supply process, at the same time to the high-speed motor has a soft stop role, reduce the impact of the starting current on the motor and the power grid, extend the service life of the equipment, improve the working efficiency of the motor, help Pingyi Tianying to complete the efficient, high-quality water supply task.

3. Application advantage

(1)FGI FD5000 high voltage frequency inverter after the installation and debugging, the equipment runs stably and the operation effect is ideal, and its overload capacity and the protection of the motor are perfectly in line with the electrical industry standards.

(2)Using FD5000 high voltage frequency inverter to control the feed pump motor, the motor can realize soft start, the starting current is less than the rated current value, and the start is smoother.

(3)According to different flow needs, DCS changes the frequency of the pump to achieve the speed of the pump, so as to control the water pressure and water flow, so that the water supply process is optimized to the maximum extent.

(4) Data statistics, the equipment running below 45 HZ, can achieve 15% -40% energy saving effect, and the energy saving effect is significant.

(5)The human-machine interface and upper function of the frequency converter display real-time parameters, including operation records, operation records, etc., to make the control more convenient.

Practice shows that FGI FD5000 series high voltage frequency inverter conversion control scheme, not only solve the application field feed pump unit equipment start shock current, speed accuracy, high maintenance cost is difficult to control the shortcomings, and effectively improve the reliability of the system operation, realize the safety, stability, energy saving more win situation, won the height of the market and customers.