1.Overview

As we all know, the cement building materials industry is a big energy consumption in the national economic production. In the process of cement production, the power consumption of the fan accounts for a very high proportion of its cost. In recent years, the state has implemented the energy saving and emission reduction policy, focusing on the cement industry. After several years of development and summary, the energy saving technology of domestic Medium Voltage Drive in the fan pump load is increasingly mature, and the effect of energy saving and emission reduction is obvious.

2.Implementation plans

The circulating fan is one of the most important equipment in the slag powder production line, and occupies the most important position in the whole process. A customer site mill in Tangshan is a vertical mill, equipped with the circulating fan is 630kW asynchronous motor, the voltage level is 10kV, the rated current is 45.3A, the fan design allowance is large, and the energy saving space is considerable. The original system in the way of power frequency directly start, start the impact, under the original industrial frequency operating conditions, the fan with the baffle adjust the air volume, usually mainly in about 60%, energy waste is serious, and the operation of real-time adjustment to ensure the normal collection of powder opening, automation level is very low, so decided to frequency conversion transformation, in order to achieve the purpose of energy saving and improve the level of automation.

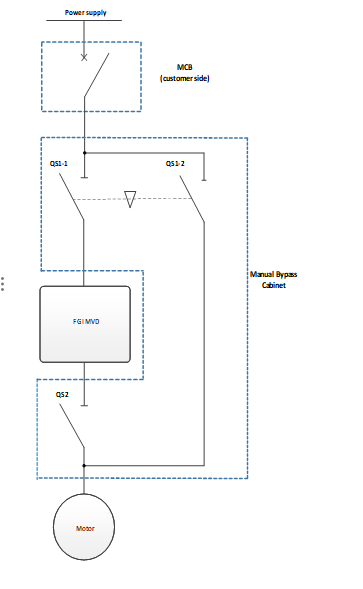

According to the field load situation, the FD5000 medium voltage drive produced by FGI is configured. The product has the advantages of vector control, good control performance, strong overload capacity, convenient operation, reliable quality and high power saving rate.

3.Application advantages

Using high-speed DSP as the central processor, faster operation speed and more accurate control.

Flying car start function. Can recognize the speed of the motor and start directly when the motor keeps turning.

Speed start. During the operation process, the high voltage instantaneous power drop is restored within 3s, and the high voltage frequency converter does not stop. After the high voltage recovery, the frequency conversion automatically runs to the frequency before the power drop.

Line voltage automatic equalization technology (star point drift technology).