1.Overview:

XDD non-ferrous metal Co., Ltd. is a large private enterprise in China, building a large modern aluminum and electricity integration plant. After the completion of the project, it will become the world's largest aluminum and electricity integration enterprise, bring great impetus to the regional economic development, and promote and promote the national "Belt and Road" development strategy.

2.Implementation plans:

Units 1 and 2 of FGI Dongfang Hope Non-ferrous Metal Co., Ltd. are 2350MW coal-fired generating units, and the boilers are sub-critical parameters, four-corner cut round combustion and natural circulation drum furnace produced by Dongfang Boiler Co., Ltd. The operating efficiency of the fan in each working condition is below 60%, the operating efficiency is low, and there is a huge energy saving space.

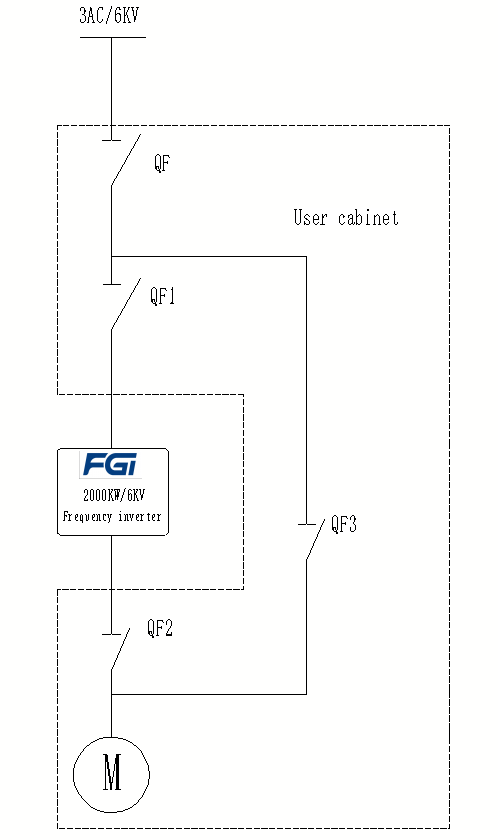

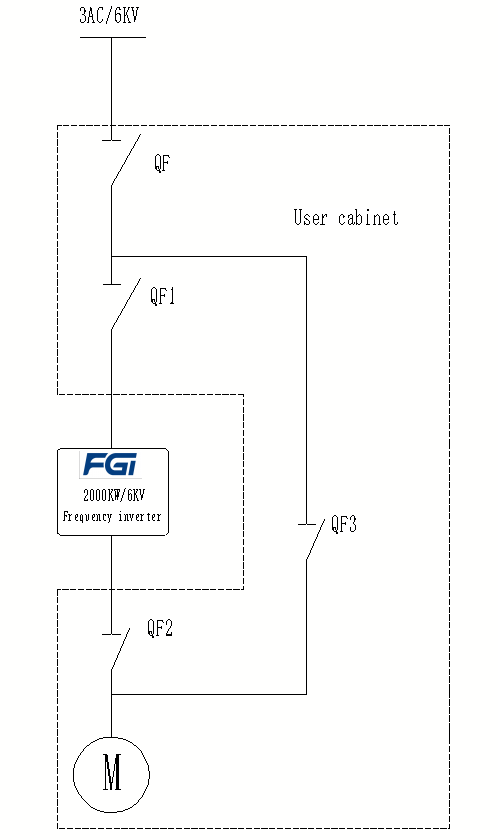

In order to meet the needs of primary wind function and power frequency startup and operation at the same time, the system adopts 1250A circuit breaker to improve the reliability. The primary system is as shown in the figure below:

QF is the user 6KV section circuit breaker, with a comprehensive protection device;

QF 1 is the frequency converter input circuit breaker, QF 2 is the frequency conversion output circuit breaker, QF 3 is the power frequency bypass circuit breaker;

There is an electrical interlock between the QF 2 and the QF 3, where one circuit breaker is closed and the other circuit breaker cannot be closed.

3.Application advantage

All the equipment will be installed in place in January 2023,3 equipment will be successfully tested at one time, and fully put into operation in March 2023, and successfully passed the 400-hour assessment in the factory, and all indicators meet the design requirements. From the actual use situation, the FGI brand high voltage inverter for primary fan has the following advantages:

1.high control accuracy, energy-saving effect is obvious. When the boiler load is 70%, the power saving rate is 43%, and when the boiler load is 80%, the power saving rate is 33%.

2.the converter system efficiency is high, the converter efficiency is more than 97%.

3. Improve the power factor of the system, reaching above 0.96.

4.start gentle, starting current is small, easy to realize automatic control.

5.can achieve the real soft start, no impact on the motor and the power grid, reduce the failure rate of the fan and the motor, reduce the maintenance costs.

6. Easy maintenance; short transformation and commissioning period; power frequency operation during fault, and the fan can be switched to power frequency operation without shutdown to improve reliability.

Practice has proved that the selection of "hope FGI" brand high voltage inverter for 1 #, 2 # furnace frequency conversion transformation is successful, the energy saving effect to achieve the expected effect. From the installation, commissioning to the final operation of the equipment, the high-voltage inverter has achieved successful commissioning, advanced product performance, excellent production and manufacturing technology, reliable product quality, and all indicators meet the requirements of the production system.