1.Overview

Winter in the north is very cold, with temperatures usually ranging from -20 to -30 degrees Celsius. In order to adapt to such weather, people in the past would set up a small furnace to heat by burning cinder blocks; nowadays, most urban areas choose to realize centralized heating through large boiler houses.

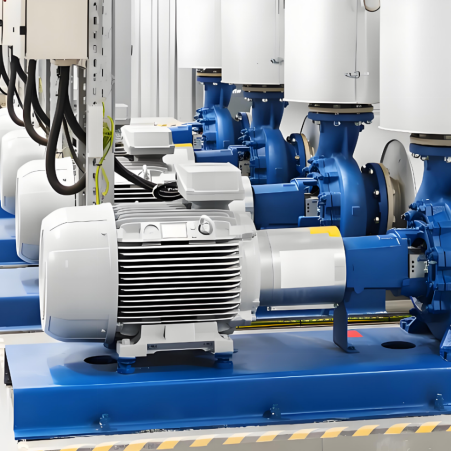

Before the transformation, people mostly use the star-delta start to drive the motor directly or use the DC governor to adjust the speed of the motor to realize the heating; in the north of a lot of large boilers on the use of FGI FD500 low frequency inverter, its efficiency and cost has been greatly improved.

2.Implementation plans

In response to the national call for FGI saving and emission reduction, small boiler rooms have basically been outlawed at present; medium-sized boilers are also retained in large cities only 50, 100 tons of these two, while large boilers are becoming more and more common.

In general, the boiler room in the motor configuration is basically as follows: 1-2 sets of make-up water pumps, a blower, an induced draft fan and 2 sets of circulating water pumps (one with a standby), and each motor will be matched with a frequency converter. Plus each node of the heat exchange station needs to use 2 circulating water pumps and 2 make-up water pumps for heat circulation. When the entire boiler room is constructed, it is necessary to give the boiler room for ignition, at this time, the first induced draft fan will be used to pump out the air inside the boiler; and the blower needs to give the boiler to deliver fresh air. In order to ensure the normal ignition of the furnace chamber, it is necessary to configure a larger power induced draft fan and a smaller power blower, so that the furnace chamber to maintain a certain negative pressure.

After normal combustion of the boiler, cold water needs to be poured into the boiler to be heated, and then the hot water inside the pipeline is sent to each heat exchange station through the circulating pump. In the process of hot water combustion, there will be a certain amount of evaporation, this time need to make up for the water pump to the pipeline to replenish a certain amount of water to maintain the pressure balance of the entire pipeline.

Frequency inverter in all the accessories connected after the corresponding test, the specific wiring of the frequency converter has the following parts: 10V, AI1, GND, AO1, X1, COM, TA and TC.

(1) AI1 and GND in the induced draft fan and blower is to receive the instrument control of the center console;

(2) AO1 and GND are to feedback the frequency of inverter to achieve the consistency of input and output;

(3) X1 and COM is to start/stop the frequency converter, TA and TC in the frequency converter alarm timely output signal, so that the personnel on the scene to notice.

(4) in the make-up water pump and circulating water pump, often used to 10V, AI1 and GND three terminals as the pressure feedback part of the frequency converter, used to receive the pressure of the pressure gauge, so as to control the speed of the frequency converter in time.

3.Application advantage

FGI saving is remarkable: saving electricity about 40%-50%, saving coal about 5%-10%.

Full combustion, less residue, effectively reduce the pollution of the environment.

Soft starting, small impact, avoid water hammer, save maintenance costs.

Stepless speed regulation, simple operation, convenient speed regulation.

Reduce the high-frequency noise of the motor, improve the environment.

Proper protection function, a variety of alarms real-time monitoring, safer, more secure.