1.Overview

As a commonly used material, plastic has the characteristics of low price, acid and alkali resistance, light weight, insulation and easy processing. Because plastics are thermoplastic, they can be produced and recycled by hot melt extrusion in industry, and can also be used in blow molding and injection molding processes. It can be widely used in various packaging, daily necessities, auto parts, industrial equipment parts.

Extruder is the core equipment of plastic production, its working principle is to stir the raw materials evenly, through the spiral material into the heating section for melting, and then through the porous plate, filter, etc., the molten plastic material extrusion into a uniform diameter, can also be directly into the mold to produce a variety of pipes, parts and so on.

FGI has extensive experience in the field of frequency inverters and has gained a high reputation for its excellent performance, providing users with higher energy efficiency and reducing energy consumption. Next, the application of FGIF300 low voltage frequency inverter in extruder is introduced.

2.Implementation plans

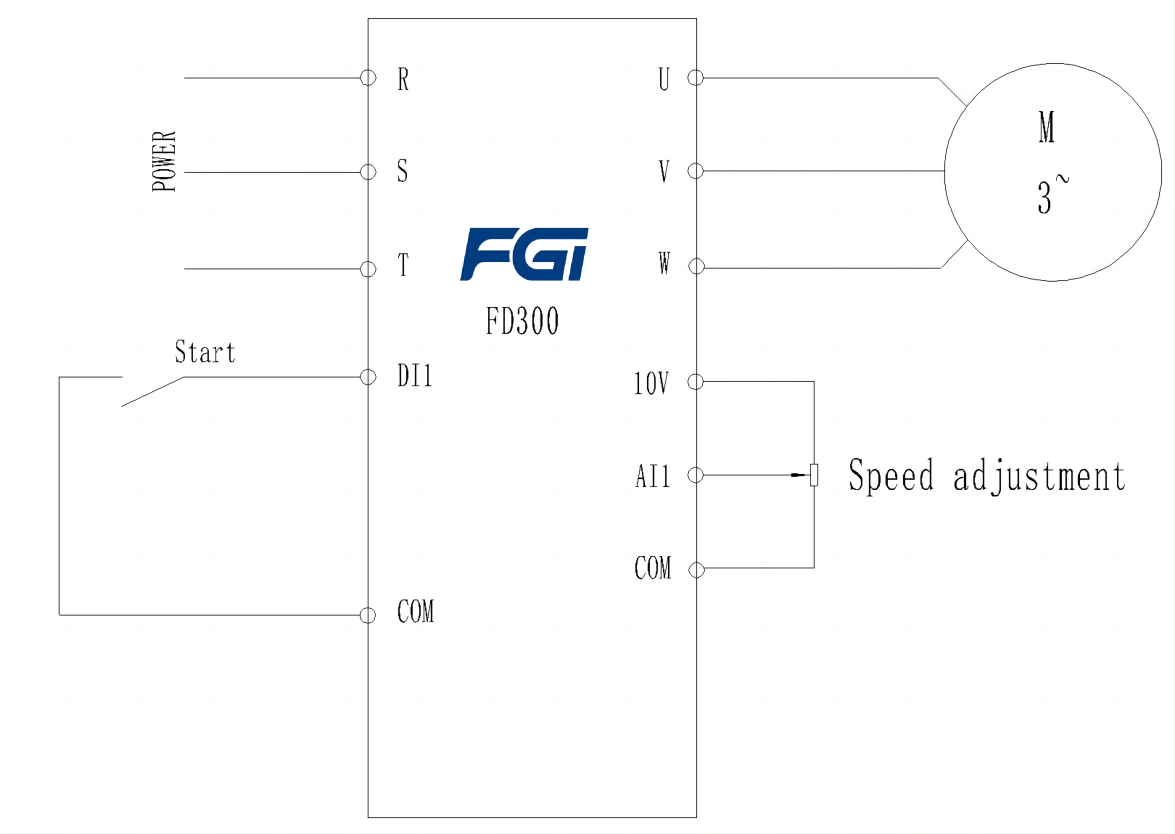

The system uses a 55 KW motor as a spiral motor, and uses a FD 300 low voltage frequency inverter -55 G/75P-4 low-voltage frequency conversion control motor to adjust the torque of the motor in real time according to the feedback current signal when the screw rotates, so as to achieve the purpose of sudden changes in spiral resistance caused by different materials and feeding speeds. Thus to ensure the smooth operation of the whole device, increase the amount of material, reduce the loss.

3. Application advantages

(1) Power saving, high efficiency: FD300 low voltage inverter with constant torque output. Compared with other speed regulating devices, its power saving rate can reach 30%, especially at low speed.

(2) Accurate control: FD300 low-voltage inverter speed regulation system has ±8% torque accuracy and ±0.5% speed accuracy, which greatly improves the control accuracy of the equipment.

(3) Improve quality: FD300 low voltage frequency inverter can effectively suppress sudden current, and can automatically adjust the spiral speed, to prevent uneven diameter, broken wire, bubbles and other quality problems.

(4) High level of automation: FD300 low voltage frequency inverter adopts frequency conversion control, with good stability and fast reaction ability.

(5) Protection device: The use of FD300 low voltage frequency inverter can reduce the loss of large current to the machine during startup and improve the service life of the machine. With over current, over voltage, under voltage, overload and other protection, overload capacity is 150%, rated current is maintained for 1 minute, to ensure the stability and reliability of the system.