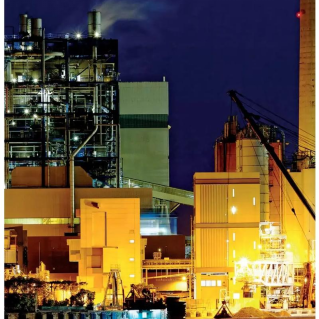

1.Overview

At present in the power plant is mainly thermal power generation and water conservancy power generation, in coal-fired power plant, because with a large number of coal power generation, coal slag or ash need to be removed, slurry pump is used in the removal of slag, slag by mixing a certain amount of water, through the slurry pump to the ash dump place, so sometimes slurry pump in power plant also become ash pump.

When the slurry pump works, the pump needs to be placed on the land, the pipe is placed in the water, and the pump needs to be started. Mud pump and under the liquid slurry pump due to the limitations of the structure, the motor needs to be placed on the surface of the work, the pump is put into the water, so it must be fixed, otherwise, the motor fell into the water will lead to the motor scrap. And because the length of the long axis is generally fixed, so the pump installation and use is more troublesome, the application of a lot of restrictions.

If there is a backup pump, it is best to use the two pumps in turn. If the pump can only repair the pump, you can add a net in the water inlet, do not let too many impurities into the pump, so that the probability of the pump will be much smaller.

The slurry pump starts and stops the motor according to the height of the front pool liquid level. In this way, there are two problems: on the one hand, in order to adapt to the requirements of the production process, we need to constantly switch, start and stop the motor according to the level of the front pool and the ash pipe every day. The height of the front pool is not well controlled, and the frequent power frequency starting motor has a great impact on the motor.

2.Implementation plans

At present, because of the valve regulation flow rate, under this adjustment mode, the system mainly has the following problems:

(1) Using slurry pump fixed speed operation, valve adjustment throttle loss, high outlet pressure, serious pipe loss, low system efficiency, resulting in energy waste.

(2) When the flow rate is reduced and the valve position opening degree is reduced, the pressure difference before and after the adjustment valve increases the working safety characteristics and become bad, and the pressure loss is serious, resulting in increased energy consumption.

(3) Long-term 40~70% valve opening accelerates the wear of the valve body itself, resulting in the deterioration of the valve control characteristics.

(4) The high pressure of the pipe network threatens the sealing performance of the system equipment, which leads to valve leakage and severe closure.

(5) Short service life of the equipment, large daily maintenance, high maintenance cost, resulting in a great waste of various resources.

One of the important means to solve the above problems is to use frequency conversion speed control technology. The FD5000 high voltage frequency inverter is used to control the motor of the slurry pump. The pressure water level sensor is set at the pool level before the slurry pump to transform the water level height signal into 4 ~ 20 mA standard signal and send the current ring interface to the frequency inverter to calculate the deviation between the current water level and the control water level, change the output frequency of the frequency inverter and adjust the speed of the motor of the slurry pump. In this way, it not only solves the control disadvantages of poor linearity and large pure hysteresis, but also improves the reliability of the system operation; more importantly, it reduces the pressure flow loss caused by the change of the control valve, reduces the wear of the control valve, reduces the damage of the sealing performance of the system, extends the service life of the equipment, reduces the maintenance, improves the economy of the system, saves energy, and provides a good way to reduce the power consumption rate of the power plant.

3.Application advantage

(1) The use of FD5000 high voltage frequency inverter can improve the reliability of system operation;

(2) The use of FD5000 high voltage frequency inverter can reduce the wear of the control valve and reduce the damage of the system to the sealing performance of the pipeline;

(3) The use of FD5000 high voltage frequency inverter can extend the service life of the equipment, reduce the amount of maintenance, improve the economy of the system, save energy, and provide a good way to reduce the power consumption rate of the power plant.