1. Foreword:

Numerical control machine tool is nearly 30 years of comprehensive application of mechanical, electrical, hydraulic, pneumatic, microelectronics and information technology as one of the electromechanical integration products, is in the mechanical manufacturing equipment with flexible, general, high precision, high efficiency of the "flexible" automatic manufacturing equipment.

The main movement of CNC machine tool is the rotating movement of the spindle through the chuck or the top driving workpiece, which is the motor drive gearbox to drive and speed. The spindle drive of the traditional machine tool requires the artificial operation of the clutch to control the speed, its operation is inconvenient, the maintenance amount is large, and the electromagnetic clutch damage rate is high.

At present, in the CNC lathe spindle drive system, the use of frequency conversion technology to adjust the speed of the spindle, the improvement of product quality, output increase, cost reduction and maintenance reduction have a decisive role, it is widely used in production. Next, we will introduce the application of FGI FD100 series frequency inverter in the CNC machine tools of a large equipment factory.

2. Equipment introduction

The CNC machine tool is mainly composed of the main engine, CNC device and drive device.

2.1Master

The main body of the CNC lathe, including the machine tool body, column, spindle, feeding mechanism and other mechanical parts. Is a mechanical component used to complete various cutting processes.

2.2 numerical control device

The core of the CNC lathe, including hardware (printed circuit board, display, key box, paper tape reader, etc.) and the corresponding software, used to input the digital parts program, and complete the input information storage, data transformation, insertion operation and the realization of various control functions.

2.3 Actuating device

Driving parts of CNC lathe actuator, including spindle drive unit, feed unit, spindle motor and feed motor, etc. Under the control of the CNC device, the main shaft and feed drive are realized through the electrical or electro-hydraulic servo system. When several feed drives are linked, the processing of positioning, straight line, plane curve and space curve can be completed.

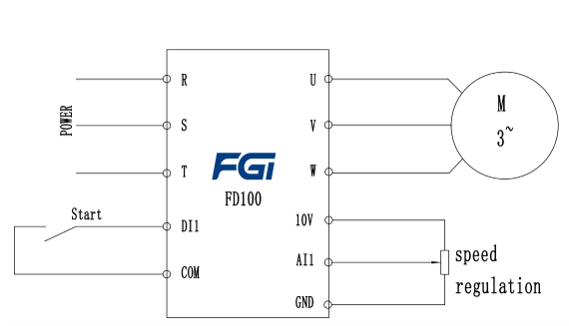

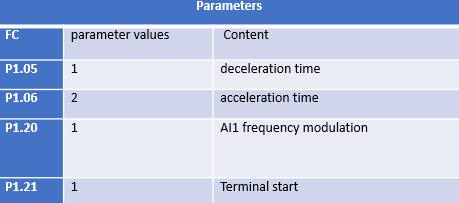

2.4 system configuration :

According to the design requirements of CNC system and machine tool design, FGI FD100 series frequency inverter is used in the site, which is applied in the lathe spindle drive system to drive the 15kW ordinary three-phase asynchronous motor to control the spindle speed regulation. The CNC device of the machine tool and the frequency inverter assist each other by setting the appropriate parameters to make the spindle motor run normally.

3. Application advantages:

3.1 Effectively reduce the cost and energy consumption

The lathe spindle drive system adopts FD 100 frequency inverter, which simplifies the original complex mechanical transmission mechanism, and makes the system simple to operate, convenient maintenance, reduce the design and maintenance costs, and at the same time, saving energy and reducing consumption.

3.2 Precise control, improve production efficiency

The FD 100 frequency inverter has advanced control algorithm, starting torque reaching 180%, speed control accuracy reaching ± 0.1% (rated synchronous speed) and speed fluctuation ± 0.1% (rated synchronous speed). While providing a large torque output for the machine tool, a wide range of stepless speed regulation is also realized. It not only improves the machining accuracy and production efficiency of the machine tool, but also meets the high depth and high strength cutting requirements of complex and irregular shape parts.

3.3 Comprehensive protection, stable and reliable operation

The FD 100 frequency inverter provides a strong overload capacity for the machine tool (150% rated current for 1 minute). And has perfect overcurrent, overpressure, underpressure and other protection functions, so that the system runs safe and reliable, deep trust of users.