1.Overview

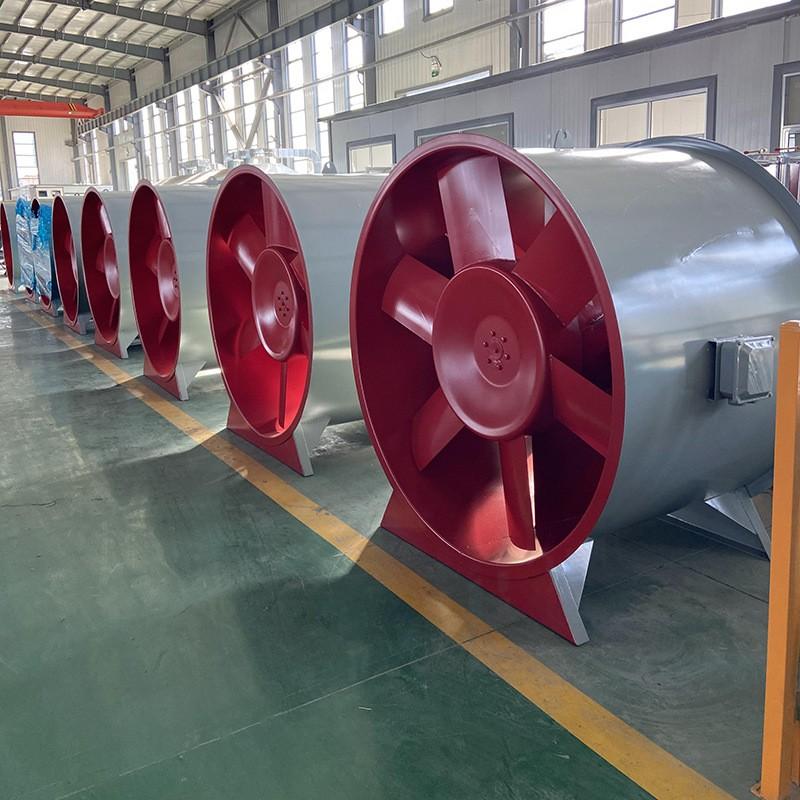

High temperature fan is a fan equipment specially designed to operate in higher temperature environment, which is widely used in various industrial fields. They are mainly used for conveying high temperature gas or for ventilation, dust removal, cooling and other work in a high temperature environment. The working environment of a high temperature fan usually requires that it can work stably at temperatures of several hundred degrees Celsius or even higher, so this kind of fan has special requirements in material selection and structural design.

2.Implementation plans

The frequency converter equipment is connected to the high voltage switch on the fan side and the motor to be reformed. The motor and the high voltage circuit breaker still use the original equipment. The original water resistance starting mode of the central control drive high voltage circuit breaker is changed to the frequency conversion control start, and the frequency converter control is connected to the original DCS system. See the figure for the main loop of the high temperature fan system. Use: FD5000 series medium voltage drive, and both QF and M are the original equipment on site.

This scheme is typical of a manual bypass scheme. The principle is composed of three high voltage disconnecting switches QS1, QS2 and QS3, and the high voltage switch MCB and motor M. Mechanical interlocking logic between QS2 and QS3 and cannot be closed simultaneously. During frequency conversion operation, QS3 is disconnected and QS1 and QS2 are closed, QS1 and QS2 are disconnected and QS3 is closed.

The FD5000 series medium voltage drive is connected into the existing high voltage switch cabinet and the high voltage motor, the three lead lines of the winding motor rotor are short connected, and the winding synchronous motor is transformed into a mouse cage motor. The variable frequency loop is used; during power frequency operation, the original starting mode is adopted, and then the three leads of the short rotor are restored, and then the power frequency can be started.

The FD5000 series medium voltage drive is installed, the original winding motor shorts the slip ring, the raw water resistance starter is abolished, the maintenance of the carbon brush and water resistance starter and motor is reduced every year, the comprehensive cost is greatly reduced, and the starting time of the high voltage inverter can be adjusted, achieving smooth start and good protection for the operation of the equipment.

3. Application advantages

(1) Realize the soft start of the motor, the starting current is less than the rated current value, and the start is smoother.

(2) The system efficiency is improved, the loss of the damper baffle is eliminated, and the energy saving effect is achieved.

(3) After the speed adjustment of the fan, the operating characteristics change, the equipment working condition is improved, and the service life of the equipment is extended.

(4) The Leadinverter is a voltage source structure with a power factor of up to 0.95.

(5) Noise pollution of plant and equipment is greatly reduced.