1.introduction

In the exploitation of shale oil and gas, fracturing technology is a commonly used technology to increase well stimulation. By injecting high pressure liquid into the rock containing oil and gas, it creates cracks in the rock layer, allowing oil and gas resources that would otherwise be unrecoverable to flow out smoothly. When shale oil and gas resources are detected somewhere, the drilling team will first carry out on-site operations and set up a drilling rig for drilling. The whole drilling process includes drilling, logging, logging, cementing and perforating.

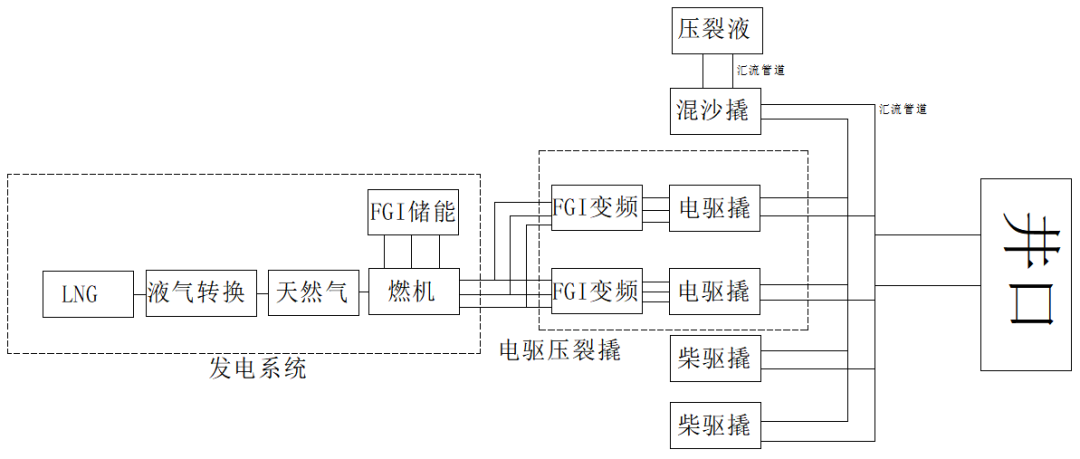

After the above steps are completed, the fracturing stage is officially entered, and the fracturing process is completed by injecting fracturing fluid into the well. There are many types of fracturing fluids injected, and there are different processes depending on the site. Fracturing equipment mainly has two driving methods: wood drive fracturing and electric drive fracturing. Wood drive fracturing is the traditional driving scheme, which has obvious shortcomings such as environmental pollution, loud noise and low power density, and the environmental protection and economy of electric drive fracturing equipment are better than traditional wood drive. FGI has introduced a system scheme of variable frequency drive and gas turbine power generation energy storage for fracturing site. The system diagram of fracturing construction site is as follows:

2. Overview of electric drive control systems.

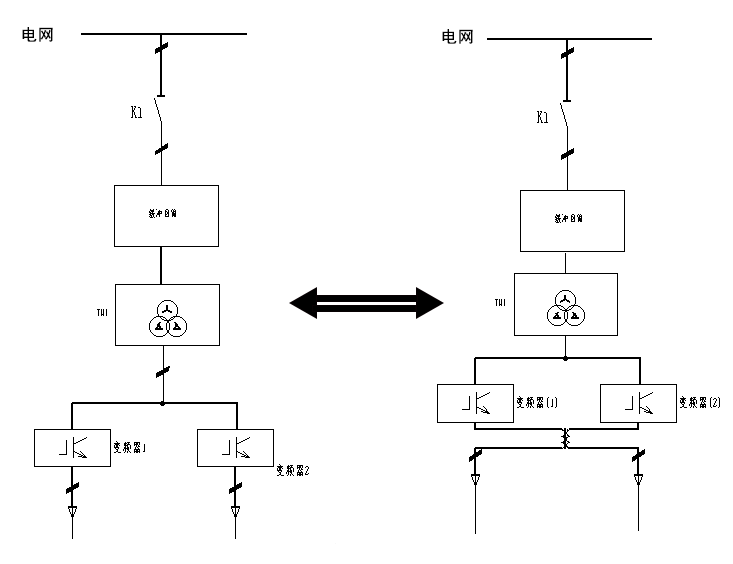

Main loop structure

In order to cope with the application of multiple pumps with different power on fracturing site, the main loop structure of the electric drive fracturing skid is adopted. The frequency inverter can independently drive two motors in single operation, and can also drive a more powerful motor in parallel operation, which greatly increases the flexibility of the frequency inverter and pump sled.

3.Gas generator and high pressure energy storage system.

(1)The energy storage system is applied at the fracturing site

Shale oil and gas are mainly distributed in remote areas such as basins and mountains, which are often not equipped with power grids. Therefore, gas turbine is often used to generate electricity in fracturing operation sites, and gas generation can adopt LNG, CNG and other gas supply methods. Compared with traditional diesel generators, gas turbine power generation has the advantages of smaller volume, lighter weight, higher single power, and less pollution. In order to improve the reliability and stability of the power system at the fracturing site, promote the saving and environmental protection of electric energy, and support the development of clean energy, the high-pressure energy storage system plays an important role in the fracturing site as the energy storage equipment at the power generation end.

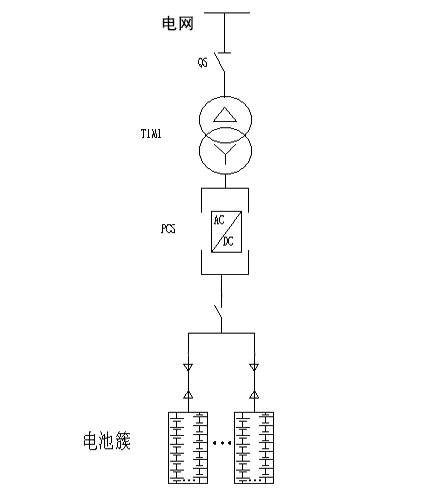

(2).High voltage energy storage system architecture

The high voltage energy storage system is mainly composed of battery, EMS system, BMS system, energy storage converter and so on. At present, batteries in high-voltage energy storage systems often use lithium iron phosphate batteries, and multiple batteries form a battery PACK, which in turn forms a battery cluster according to different combinations. The energy management system (EMS) is mainly used to control the energy inside the power grid, maintain the power balance of the power grid, and ensure the normal operation of the power grid. BMS system, the battery management system, is mainly to intelligently manage and maintain each battery unit, prevent the battery from overcharging and overdischarging, extend the service life of the battery, and monitor the status of the battery. The energy storage converter, also known as PCS, is a conversion device between the power grid AC and the battery DC, AC/DC is the charging process, DC/AC is the discharge process.

4.TAG

The electric drive fracturing skid is an inevitable development trend in the future fracturing industry. FGI uses its self-developed electric drive fracturing skid frequency converter and energy storage system solutions to be increasingly mature in fracturing applications. After continuous field application and the passage of time, it outputs a strong driving force for the cost reduction, energy saving and emission reduction of the shale oil and gas fracturing industry. Ingenuity to create fracturing equipment, cast high-quality products. The continuous innovation model provides a strong driving force for FGI, and promotes its excellent product quality and excellent service to lead the development of the industry.