Today, we share the case of "a frequency converter independently driving two motors", which has been actually applied to products, mass production of thousands of units, zero failure and zero complaints over the years, is one of the effective means to reduce costs.

Note: In this case, one inverter cannot drive two motors at the same time, only two motors can operate independently under logical control.

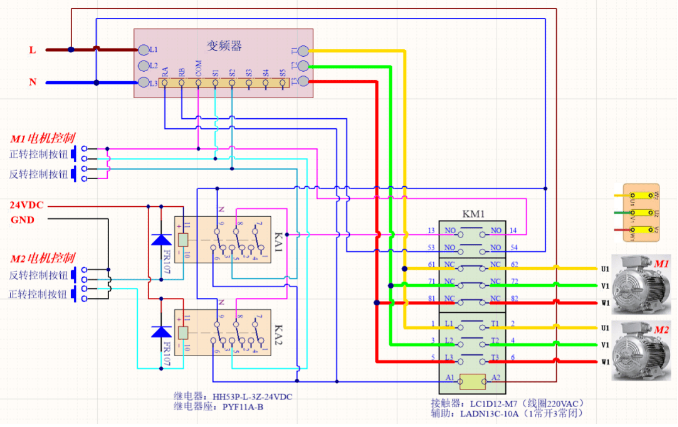

Implementation process: (If you want to realize the logic control of single chip microcomputer or PLC, just change the button to the relay contact output of the controller)

① Press any M1 motor control button, KA1, KA2, KM1 do not operate, inverter output directly through the three normally closed contacts of KM1 output to M1 motor;

(2) Press the M2 motor forward control button, KA2 control KM1 after suction, so that the neutral line passes through the 53/54 contact of KM1 through the frequency converter RA/RB contact and the KM1 coil is maintained, and the frequency converter COM and S1 are switched on to control the frequency converter, and the frequency converter output is output to the M2 motor through the closed contact of KM1;

③ Lift the M2 motor forward control button, the frequency converter decelerates and stops running, the frequency converter RA/RB contact is disconnected, and the KM1 coil loses power; Reverse control is exactly the same.

Logical sequence: contactor suction → inverter operation → inverter stop → contactor release