The Great Wall Six Mine is located in Shanghai Miao Economic Development Zone, Etoke Front Banner, Inner Mongolia. It started construction in September 2012 and won the "Sun Cup" of coal industry engineering quality. The designed production capacity of the mine is 1.5 million tons/year, the coal reserves are 135 million tons, and the stability and continuity of the coal seam are good. The main coal seam is 3,5,9 coal, which is a good coal seam with good occurrence conditions in Shanghai Miao mining area.

The Great Wall Six Mine firmly establishes the operation concept of "light assets, fine labor, low cost and high efficiency", firmly innovated enterprises and innovated as the soul, deeply optimized innovation and planted development advantages, carried out subversive optimization of the well system, and planned the long-term production mode positioning of "2 fully mechanized mining faces, 3 digging heads, 300 underground workers, and strive for 10,000 tons per capita". Strive to create a "safe, efficient, green, smart" type of modern mine.

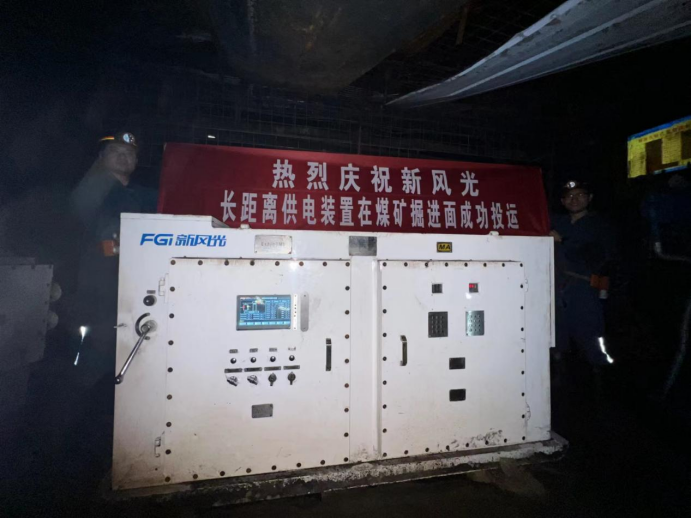

At present, the long distance power supply comprehensive treatment device delivered by FGI for 1501N driving face of Changcheng No. 6 Mine in Shanghai Miao Mining Area, Inner Mongolia, has been in safe operation for one year. The back-end load power is mainly 260kW, EBZ260 type of boring machine. This is the third mine and the fifth excavation face served by FGI in the Shanghai Miao Mine Area.

Application site of long distance power supply comprehensive treatment device in Changcheng Six mine

FGI long distance power supply comprehensive treatment device, using reactive power compensation and cable voltage drop composite control strategy, quickly realize voltage compensation and power factor improvement, 3.3kV products can solve the problem of 5000m long distance power supply of fully mechanized coal miner equipment; The 1140V product can automatically compensate the cable voltage drop according to the cable length to achieve 3000m long distance power supply at the driving surface. The system completely solves the phenomenon that the power supply voltage of the heading head is greatly reduced due to the operation or start-up of the equipment, and avoids various other problems caused by the voltage reduction of the equipment startup failure or unstable operation, so as to achieve a breakthrough in the bottleneck of the coal production industry, and improve the power factor of the entire heading face through reactive power compensation, so as to achieve energy saving and emission reduction. It can help improve the efficiency of coal production, reduce production costs and improve the reliability of power supply. In addition, by improving the traditional coal mining production technology, the number of underground workers is greatly reduced, the labor intensity of miners is effectively reduced, and the work safety is improved.

The long distance power supply comprehensive treatment device of the sixth Great Wall Mine was put into operation

After the device is applied to the underground mining and coal mining face, the power supply distance between the mobile transformer and the post-load equipment can be greatly extended from the existing 1000 meters to 5000 meters, avoiding the frequent moving of the transformer equipment due to the low voltage of the end power supply, reducing the work intensity of the underground mining and coal mining face, and improving the work efficiency. The system realizes automatic reactive power adjustment, voltage compensation, reactive power compensation, harmonic compensation, improve the quality of power supply, protect electrical equipment, reduce the failure rate, and can increase the power factor to more than 0.95; To achieve energy saving and consumption reduction, it is expected to save 1.2 million yuan of labor costs for laying cables and installing and moving distribution points, reduce the investment of cables and electrical equipment by about 400,000 yuan, reduce the number of stops, and increase the per capita efficiency by about 20%.

The successful and reliable operation practice of the FGI long-distance power supply device shows that the technical solution can be applied to domestic and foreign coal mine underground driving face and even coal face where long-distance power supply is needed, and can be widely promoted in other mining enterprises in the country to improve the inefficient means of the current driving production process, and has a broad market promotion and application scenario.

FGI long distance power supply comprehensive treatment device

FGI has served the coal mining industry for more than 30 years, providing five series of products and services of "less electricity, good use of electricity, renewable electricity, storage electricity, explosion-proof electricity", among which the newly developed long-distance power supply device and energy storage inverter fill the domestic gap. In recent years, with the promotion of the national strategy of the Belt and Road, FGI long-distance power supply devices have been going out of the country, serving various long-distance power supply sites in more than 10 countries and regions such as Russia, Laos and Serbia. Adhering to the development concept of "unlimited green electricity", FGI uses safe and efficient power supply system solutions to implement the Belt and Road strategy and accelerate the international layout.